Hello Everyone, this is my first post on the forum but have been lurking for quite a few years. First I have to say thanks to everyone who has contributed to this forum over the years and helped the development of water and alcohol injection.

Seeing as there is a limited amount of information being shared I want to provide some insight on what I have put together in this application in the event anyone else can benifit from it and ask a question or two.

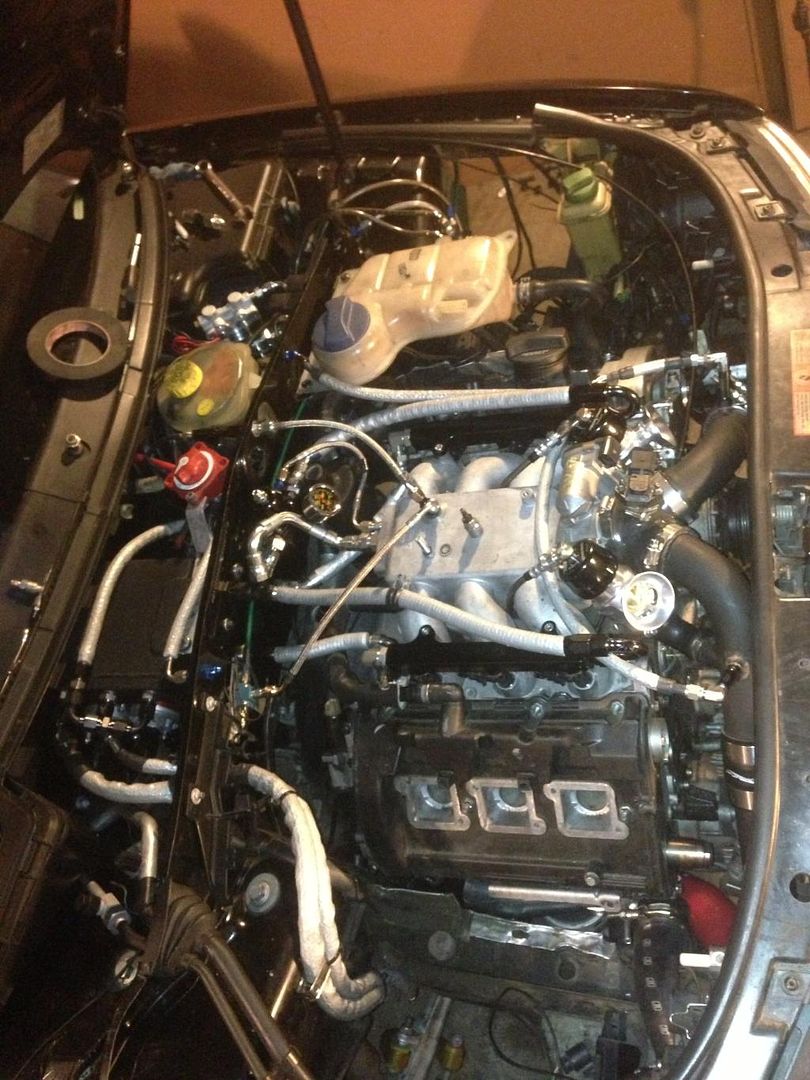

The car is a 2001.5 audi b5 s4, I raised the compression rato to 10.5:1 and have bored the cylinders out to around 2.9 liters of displacement. The car is currently set up with 1000cc injectors for the fuel circut and the turbos are K24's. I'm currently running without intercoolers but plan to re-install them in the summer months and log the differences. The car is almost complete and I should have it on the dyno in a few weeks.

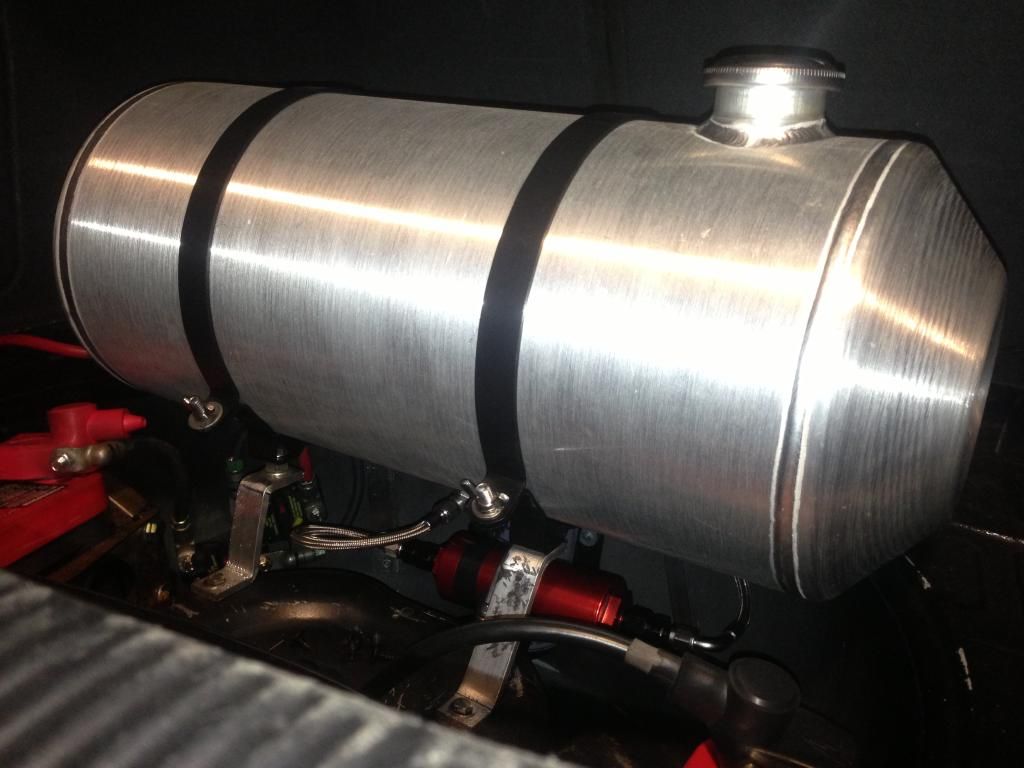

As for the water injection, I plan on running de-ionised water and isopropanol.*

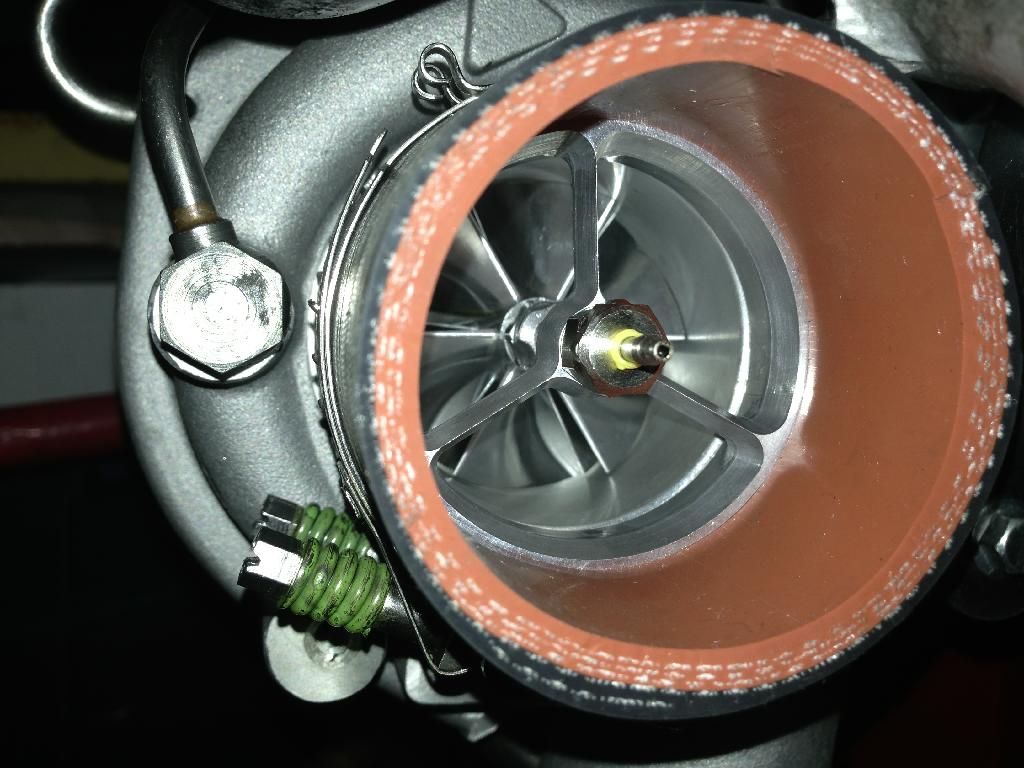

The pump is the same aquatec unit that aquamist, aem and devilsown provide. The lines are all ptfe lined, stainless braided *in -4 with repect to the pre turbo T which goes from -4 to -2. Also worth noting, all of the -4 fittings are crimped, not the rebuildable type. I have placed two injectors, one for each turbo about 6" before the throttlebody using 550cc jets on each side. I gave a call to Jeff at howerton engineering who got me set up with a pair of the beautiful axial brackets which I first read about here (thank you Richard) and am using 150cc jets in each bracket.*

I originally set up the system with a solenoid consisting of two ports, one in and one out. The pre turbo injectors are aquamist and the post turbo ones are aem and have check valves integrated into the injector bodies.

I decided after bench testing the system that i was not comfortable with the way the line pressure diminished in all four injection points, the way it tapered down pre turbo specifically after the solenoid had shut. After searching around and making some calls I was able to have a custom solenoid made that consists of two seperate coils and plungers with the capability of controlling two injection points independently. The port configuration has one in, two outs and a common exhaust port shared by both outs in the normally closed state. My intent is to have the line pressure pre turbo and tb diminish as soon as the solenoid closes helping the check valves to actually shut instead of taper down leaving solid drops where they shouldn't be.

Just to elaborate alittle further,*

port 1 is the pressure source

port 2 is the exhaust port, which will run to the washer reservoir

port 3 is pre throttle body

port 4 is pre turbo

Question 1, Has anyone else set up a system similar to this?

Question 2, I am considering swapping out my manual transmission radiator and using one with a built in oil cooler with the intent of running the alcohol through it. I'm hoping the extra heat transfer will be of some benefit in regards to line pressure, atomization and poential ratios of water to isopropanol. Has anyone tried this?

Thanks in advance, Marc

Pics for the curious:

-2 an line to pre turbo injectors was a perfect fit in the sai ports with a little massaging:

I havent put back in the pre turbo and exhaust lines but you can get an idea of the setup: