|

|

#1

|

|||

|

|||

|

Hello Everyone, this is my first post on the forum but have been lurking for quite a few years. First I have to say thanks to everyone who has contributed to this forum over the years and helped the development of water and alcohol injection.

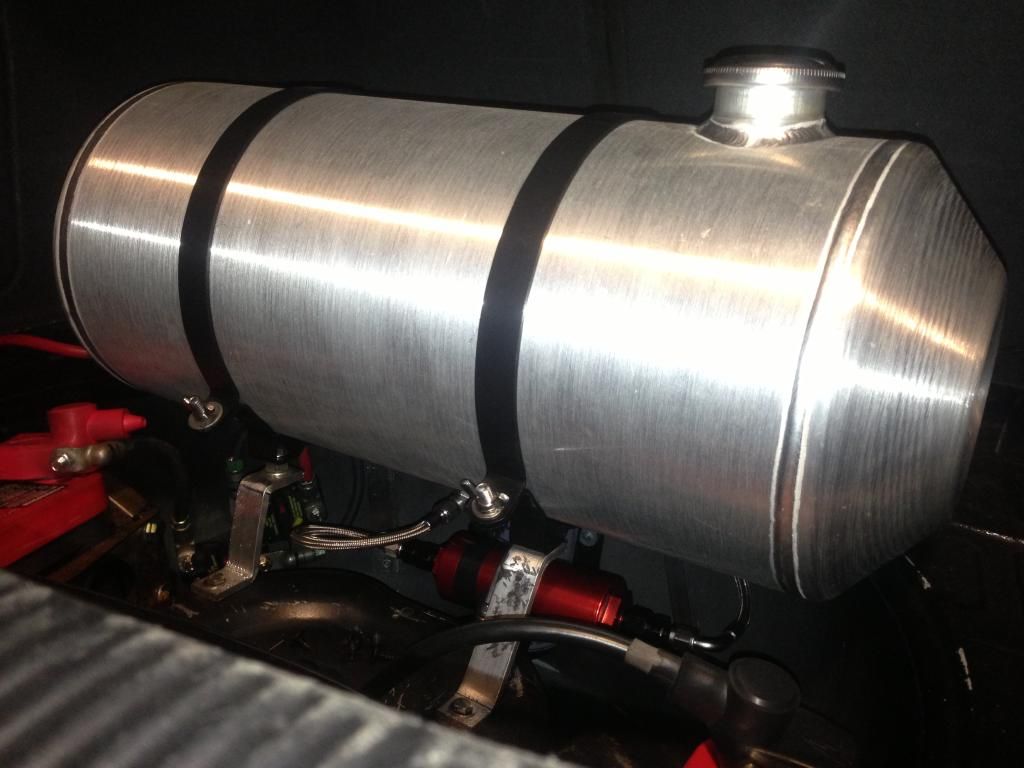

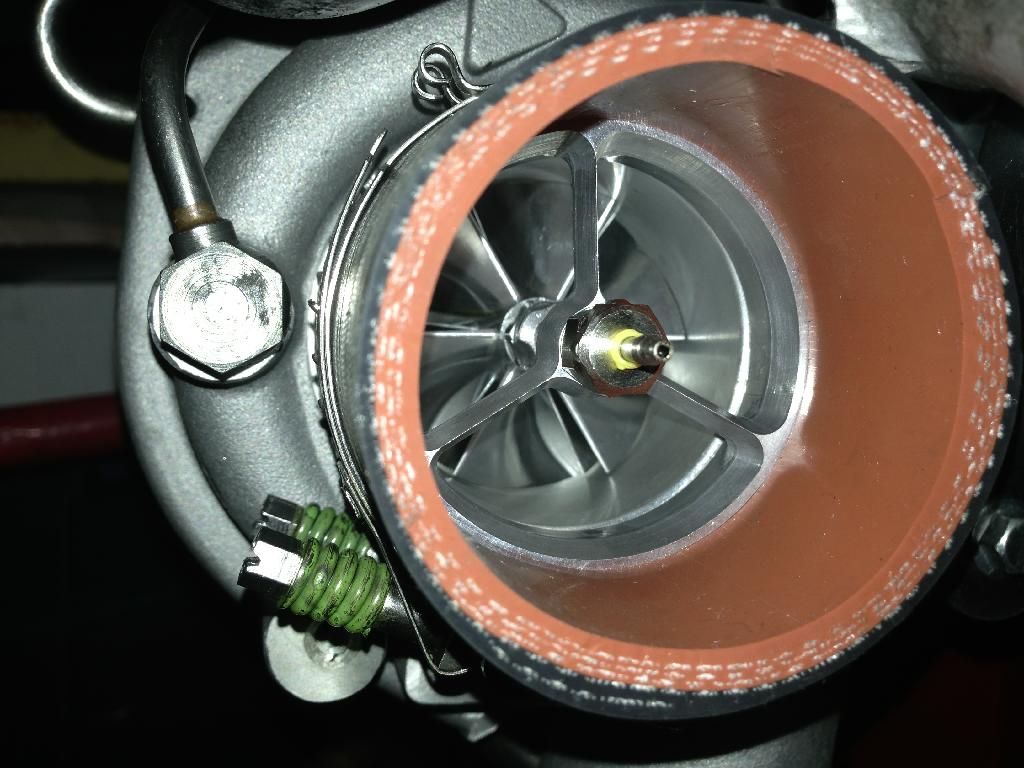

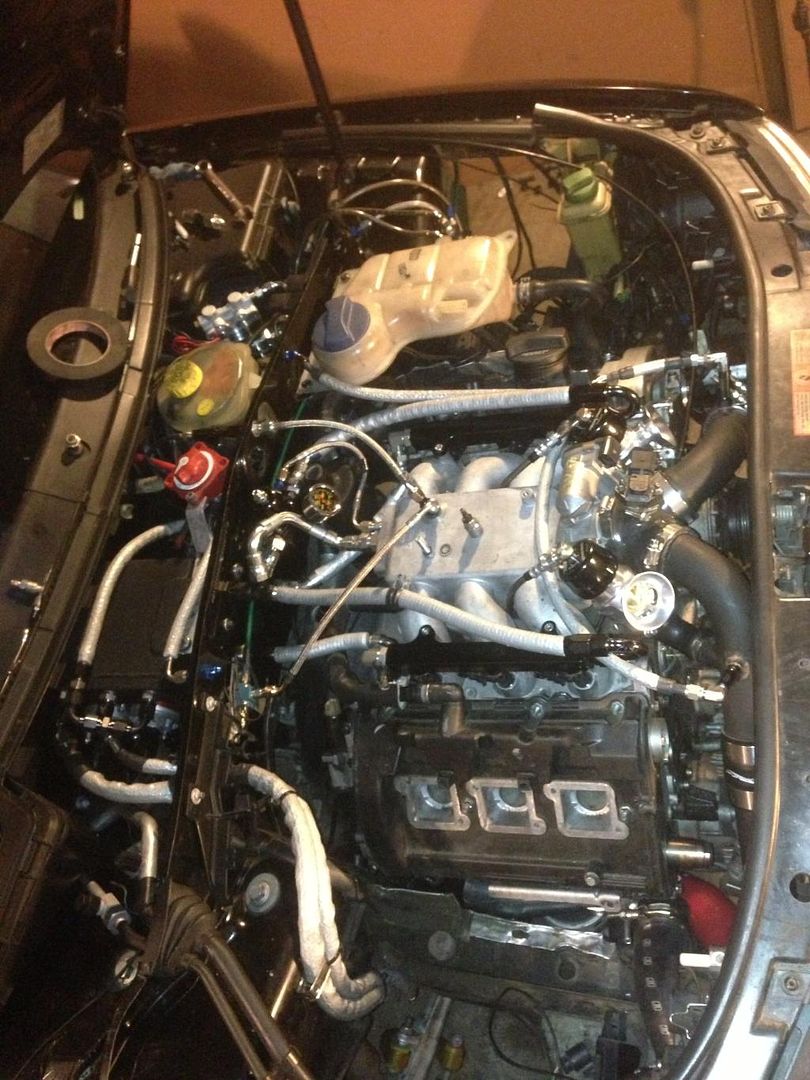

Seeing as there is a limited amount of information being shared I want to provide some insight on what I have put together in this application in the event anyone else can benifit from it and ask a question or two. The car is a 2001.5 audi b5 s4, I raised the compression rato to 10.5:1 and have bored the cylinders out to around 2.9 liters of displacement. The car is currently set up with 1000cc injectors for the fuel circut and the turbos are K24's. I'm currently running without intercoolers but plan to re-install them in the summer months and log the differences. The car is almost complete and I should have it on the dyno in a few weeks. As for the water injection, I plan on running de-ionised water and isopropanol.* The pump is the same aquatec unit that aquamist, aem and devilsown provide. The lines are all ptfe lined, stainless braided *in -4 with repect to the pre turbo T which goes from -4 to -2. Also worth noting, all of the -4 fittings are crimped, not the rebuildable type. I have placed two injectors, one for each turbo about 6" before the throttlebody using 550cc jets on each side. I gave a call to Jeff at howerton engineering who got me set up with a pair of the beautiful axial brackets which I first read about here (thank you Richard) and am using 150cc jets in each bracket.* I originally set up the system with a solenoid consisting of two ports, one in and one out. The pre turbo injectors are aquamist and the post turbo ones are aem and have check valves integrated into the injector bodies. I decided after bench testing the system that i was not comfortable with the way the line pressure diminished in all four injection points, the way it tapered down pre turbo specifically after the solenoid had shut. After searching around and making some calls I was able to have a custom solenoid made that consists of two seperate coils and plungers with the capability of controlling two injection points independently. The port configuration has one in, two outs and a common exhaust port shared by both outs in the normally closed state. My intent is to have the line pressure pre turbo and tb diminish as soon as the solenoid closes helping the check valves to actually shut instead of taper down leaving solid drops where they shouldn't be. Just to elaborate alittle further,* port 1 is the pressure source port 2 is the exhaust port, which will run to the washer reservoir port 3 is pre throttle body port 4 is pre turbo Question 1, Has anyone else set up a system similar to this? Question 2, I am considering swapping out my manual transmission radiator and using one with a built in oil cooler with the intent of running the alcohol through it. I'm hoping the extra heat transfer will be of some benefit in regards to line pressure, atomization and poential ratios of water to isopropanol. Has anyone tried this? Thanks in advance, Marc Pics for the curious:        -2 an line to pre turbo injectors was a perfect fit in the sai ports with a little massaging:   I havent put back in the pre turbo and exhaust lines but you can get an idea of the setup:

Last edited by cinesnow; 14-12-2014 at 10:00 PM. |

|

#2

|

|||

|

|||

|

Nice work on the setup, I'll be testing a small .3mm Aquamist jet pre-turbo on a TSI engine in my MK6 GTI. I don't have access to the turbine wheel like you do with my K04 turbo so I decided to set the jet way farther back right at post MAF. I'll trigger it at high boost with a boost switch a separate solenoid fed from the line pre-FAV (non-progressive basically).

|

|

#3

|

|||

|

|||

|

Hi Marc,

Nice work indeed and I am sure you thought much about it. I didn't understood well the solenoid system although it seems a little complicated and prone to fail or else not be precise as it should. I am not arguing about your system but maybe I could suggest you a better way of what I have in my mind for my current setup. I am running a 1.5L GT28 turbo target of 340bhp @ 22psi. Currently using post water (only) injection but considering pre-turbo. I have the AEM injection system running 350cc post turbo and thinking of 150cc pre-turbo. Now since I have no intercooler, I am starting injection about 3psi with a gradual increase until full flow @ 150psi pump pressure till 18psi boost. Now I wanted pre-turbo to begin at least @ 10psi boost. I intend to use a variable cracking pressure check valve mounted directly with the AEM nozzle and thinking of setting 100psi cracking pressure. This way you simply make sure that injection is pressurized enough to mist preventing blade damage and maximum atmoization. You only need to adjust correctly the check valve. Here is the check valve in subject : http://www.ham-let.com/catalogue/product/7853 Regarding question 2 : I tried to use the same theory but instead of radiator heat turbine exhaust heat ! I used a braided pipe from pump to engine bay and converted to a stainless brake line. Welded bracket to the brake line to a spacer that fits into three bolts of the turbine housing. After testing, it eventually gave no positive results but instead exhaust heat was actually heating the intake through the line and nozzle! To make sure the thoery of heating the liquid could make a difference .... try this as it was eventually easier to do ! Boil the distilled water using a kettle and pour nto the empty tank. Heat enough water and go for a ride immidiately after to test it. I did it and eventually gave negative results of increased air temps by 10C ! Good luck |

|

#4

|

|||

|

|||

|

Parmas,

Thanks for the input, I was thinking a check valve would be essential but wasn't sure on cracking pressure yet, i'll order some of those check valves and see how it functions again soon. With the check valves, the line sould keep filled and only discharge the line pressure back through the solenoid and into the washer res. To make sure it donen't drain the line between the solenoid and injectors, introducing air - I made sure to have the exhaust line higher than the rest of the circut. Today I decided to do a threshold test on a stock audi radiator with an integrated gearbox cooler. I cut down the flanges and tapped the ports for -6 and put it on the test bench, It held up to 700 psi and ruptured internally at 800. I don't expect that the trans cooler portion of the radiator would ever see more than 300'ish psi in operation, but we'll see what happens once it's set up. Very interesting setup with the braided line, do you have any pics? 10*c is a huge rise! More to come soon...

Last edited by cinesnow; 15-12-2014 at 08:57 PM. |

|

#5

|

|||

|

|||

|

Quote:

Last edited by parmas; 16-12-2014 at 12:43 PM. |

|

#6

|

|||

|

|||

|

Parmas,

Thanks for the formula and That car of your looks like a rocket, what does it weigh? I'll be sure to set everything up with the check valves once Iv'e optimised the injection start points. The ham-let check valves are really nice, just waiting for them to email back so I can get them ordered. The radiator would be used to heat the alcohol line, I'm going to conduct my first set of tests on the dyno without it and come back to this concept after everything else is dialed in. Last edited by cinesnow; 17-12-2014 at 06:46 PM. |

|

#7

|

|||

|

|||

|

Quote:

|

|

#8

|

|||

|

|||

|

Parmas,

I got abold of somone over there, will see them in about five weeks or so. You were right about the water and kettle trick, too close to the boiling point was a negative effect. Wasn't sure about having an alcohol mix in it but I definately agree that heating iso would also be a very bad idea. |

|

#9

|

|||

|

|||

|

Quote:

Also do not try to cool the water as I tried it aswell and was a negative result! For once it seems that better leave it to whatever the ambient temp is |

|

#10

|

|||

|

|||

|

I have tried precompression injection with a Rotrex C30-74. I took pictures of the turbine wheel before and after some use and could not spot a single difference except the blades looked more clean.

Powerwise I did not make any feelable difference comparted to direct port injection with similar flow. I injected 300ml/min. The sound of the supercharger changes a bit. You can hear more of a noise. Intake asir temps drop to ambient using 50/50 water methanol. The nozzle was positioned about 5" away from the intake that was S-shaped. I positioned in a way it would not pool on a wall. |

|

|

|