|

|

#1

|

|||

|

|||

|

Hello guys.

Great forms here. I was always interested in alternative fuels/exotic fuel mixes and multifuel setups as a means of increasing performance or a car engine. Anyways, long story short, i'm rebuilding e30 bmw 325i engine (L6, sohc, 2V, wasted spark igniton, megasquirt standalone ecu) with a turbo on it. Aswell i decided to install WI system, esp for experimenting with different special fuels (combination(s) of water/ethanol/methanol/toulene/acetone/nitromethane/whatever else i can find that goes 'boom' :twisted: ) Standalone ECU will have a whole separate injection channel to drive WI, so i can tune WI with it's own separate VE map (just like fuel) so here are two different setups i'm thinking about. I'm trying to decide which would be better. Of course i would like to spend as least as possible, but i dont mind spending bit extra for bit extra functionality/assurance/value. So: Option 1: Batch fired port system. would need 6 small nozzles installed in each port. suitable water pump. one big fast acting solenoid valve. no FPR. Can thoe fast acting solenoid valves open and close as fast as injectors ? in low boost situations i might require only, eg 3ms PW worth of WI injectoed, can those valves operate at those levels ? note that all nozzles will be hooed up to this one central valve, so it has to provide enough flow. Option 2: Multiple nozzles in the intake, just after IC, with a twist. In this situation i dont think pulsing jets are a good solutions, because these create 'areas' of more or less saturates 'mixture' Instead I'm thinking about, say 6 small valves (sizing to be confirmed. possibly different sizes would work better, like 1st jet big, rest smallish), that would be actuated in following way: at 2 psi of boost first one opens and keeps open until boost above 2 psi. once (say) 5 psi is reached, another one opens (again 100%DC) and keeps open until boost is abouve this threshold. same for all other nozzles, each opens at higher boost treshold. I'm leaning towards option 2, because with option 2, WI has much more time to evaporate in charge air and therefore bring the chage temps down. downside is that ti would requires possibly quite complex controller to operate well... I'm looking for pro's opinions about those 2 options. I do not have any practical Wi experience myself, so your input is highly valuable. Thanks, Mops. or perhaps a hybrid of both ? one big nozzle after ic + port nozzles for fine tuning. |

|

#2

|

|||

|

|||

|

Most people with port injection also have an additional jet located at the exit of the intercooler for charge air cooling.

Port injectors has to be small so if one is partially clogged, it won't cause any damage to one particular cyclinder. There isn't a failsafe system that will be sensitive enough to detect an individual clogged jet. Never say never, however careful.

__________________

Richard L aquamist technical support |

|

#3

|

|||

|

|||

This is my arrangement, 6 port 0.3mm nozzles (for knock control), a 1mm jet on the rear turbo exit (runs hotter than the front) and a 0.9mm jet pre throttle body. All fire at the same time fed by a Shuflow pump in the boot. I`ve set the WI to inject at 9psi upwards, as a failsafe my boost controller will only operate when AFR`s are 11.5 or richer, leaner and the car runs wastegate pressure (7psi). What I`ve found is it takes roughly a second for the WI to hit the chambers and affect the AFR (I`m running 75%methanol 25%water), with this setup if the car runs lean due to WI lag or failure the car will never boost high enough to get into the lean/ agressive part of the fuel map. Seems to be a good way to go about it when the alcohol injected is relied upon as a fuel. I taper the petrol/fuel off in the map from 9psi to fully alcohol saturated at 11 psi, so there is a gradual ramp as the WI comes in. It works very well for me, had good results and no knock as the fuel and ignition maps can`t jump into a WI zone without there being sufficient injection first, before the 1 secong lag could set off knock in the engine. Plus if the WI tank runs dry the car will never hit over 7psi which is a "safe" part of the ignition and fuel maps.

__________________

VW Mk2 Golf 16VG60 - Mitsubishi GTO TT |

|

#4

|

|||

|

|||

|

That's some good info.

but i don't 100% understand the way you are controlling it.... you are saying that if you are too lean, then boost will stay low. aswell if you run out of WI (meth in your case), the boost will stay low too. that is awesome. how is that controlled ? because just like you, my injectors will only handle so much boost/hp, if i want to go further I'll have to reply on wi delivering extra fuel (possibly i'm considering preturbo extra fuel injector ?) Aswell i dont understand your injection staging. are you saying they all activate at once? at 7 psi of boost ? all including those port ones ? just as your system, i'd like to build in some sort of safety, ie. if no WI pressure then the boost will stay low. this could be done by bleeding some pressure to the top of the external wastegate (bleed 3 psi there, boost will incerase by 3 psi - that's the system porsche used to have in their racecars.) at this stage i'm leaning towards my option 2. I already have some thought about the controller. it will be really cheap and effective. one of those DIY kits form local electronic store that show injector DC using 10 led's (each led=10%). basically higher injector DC=more fuel=more air=more Wi to inject. Say i hook up nothing to 10-40% leds, then to 50% led i hookup big nozzle (for 50% of hp capacity of the engine), then each 10% led get's s smaller jet.... there's some calibration possible with nozzle sizes AND with the sensivity of the DC sensing circuit. aswell with this setup i can use cheap solenoid valves, not those expensive fast acting ones.... possibly some nozzle(s) can be installed preturbo... on the other hand, i think port injection is good too, because unvaporised droplets make it to combustion chamber and vaporize there, cooling it down (imho this has greater effect than cooling charge, but what do i know...) decisions, decisions... |

|

#5

|

|||

|

|||

|

All the injectors fire at the same time from the main pump, I`m using a Greddy Emanage to map my fuel and ignition; it also controls the WI (9psi).

I`ve wired my Wideband AFR meter and Boost controller via a switch circuit so a lean condition will shut off the boost controller and drop boost to wastegate pressure. My fuel map leans out after 9psi, if the WI is working correctly the AFR will remain at 11.5:1 because of the added alcohol and the boost controller will be active. If the WI fails the AFR will be leaner than 11.5:1 (above 9psi) this will imediately shut down the boost controller and I`ll be back at wastegate pressure. What happens in practice is the AFR will be at 11.5:1 at 9psi, it`ll hover at 9-10psi for a second or two (alcohol hasn`t had time to enter the combustion chambers yet, over 9psi the fuel is being trimmed out so AFR is too lean to turn on boost controller), once the alchohol gets going the AFR`s will hold 11.5:1 all the way into boost and redline.

__________________

VW Mk2 Golf 16VG60 - Mitsubishi GTO TT |

|

#6

|

|||

|

|||

|

Nice setup.

So basically you are saying that WI starts a 9 psi, and once afr's go rich then extra boost kicks in. That is pretty much how i want my setup to me. daily driven, say 10 psi (no WI), then once switch is actiwated, WI and extra boost (say 15 psi) kicks in... |

|

#7

|

|||

|

|||

|

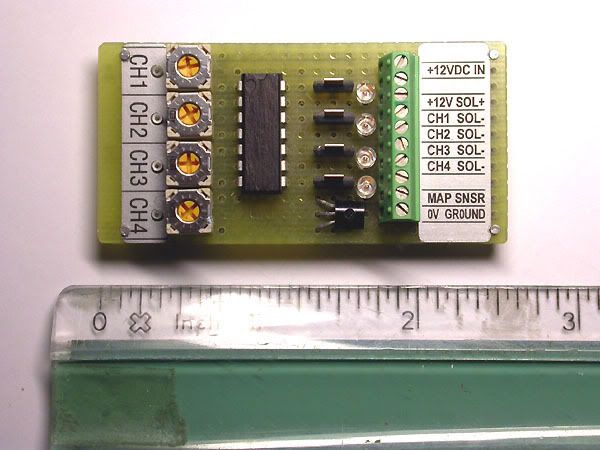

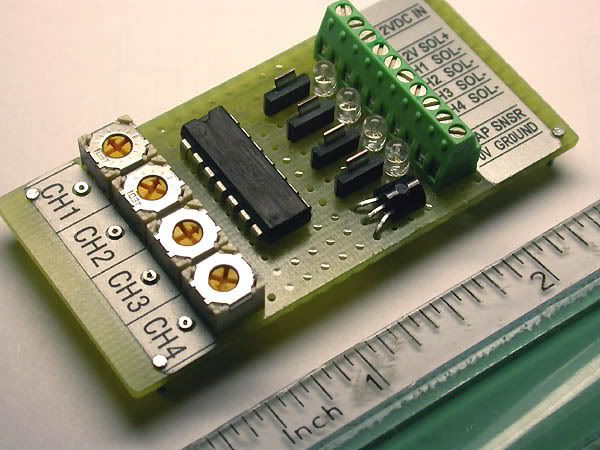

We have a highspeed valve that might be able to fit your application, It takes 1.8ms to open amd 1.8ms to shut.

Alternative option - a 3-stage system (CH-1 to activate the pump relay): Please the link below: http://www.srtforums.com/forums/show...=388723&page=3

__________________

Richard L aquamist technical support |

|

|

|