|

|

#491

|

|||

|

|||

|

Instead of looking at it as percent airflow increase, you may want to also plot it as ve increase. You can compare curves rather than peak values.

|

|

#492

|

|||

|

|||

|

Here is my opinion of PRE-Turbo Water injection after reading all posts:

1. Nozzle Position : I am really surprised how in 9 years time, there is not a definitive answer on where to position the nozzle in a pre-turbo application. Some are saying directly to impeller will prevent blade damage but would result in abnormal airflow while others a few inches away or exactly on the filter will have the maximum time to atmoize and mix with Air. What if we position the nozzle infront of the compressor wheel but instead injecting exactly the opposite way? Let's say we are activating at 10psi, the high intake flow coming from the filter will push the mist back into the compressor forming an umbrella type of mist. What do you think about it? Check attachment 2. Nozzle Size vs Head Flow: Again after reading all posts, it seems that many of you are going insane flow levels and above recommended nozzle size. Some seen also wheel damage because of that. When we are talking pre-turbo, I agree with some of you that nozzle size should be between 10-50micron or 0.01-0.05mm. A 130cc/min nozzle is a 0.4mm while a 50micron is 16cc/min at the same pressure. The flow seems low compared to others flowing 200+ cc/min. True FOG is 30micron. Quote : "If you are injecting pre-compressor at 2%-3% rate compared to air flow you will have about all the WI you need. Suppose you spray at 2% air flow rate, and you have a 11.5:1 fuel air ratio at red line. If you are flowing 65 lb/min, that is 29510 grams of air per min. At 2% flow that means you would be injecting 590 grams / min of water. If you have an 11.5:1 air fuel ratio than your fuel is 29510/11.5 = 2566 grams / min Since most gasoline has a density of about .78 then that is 3289 cc/min 10% water to fuel would be 329 cc/min 15% water to fuel would be 493 cc/min You would be spraying about 18% per min to fuel if you sprayed 2% of air by weight with a max power AFR of 11.5:1. The beauty of using the air flow is is self corrects as you lean out the fuel. the higher your AFR (say 12.5:1) the higher your percentage of water/fuel at a fixed water to air ratio. 3. Injection Pressure : This is no taboo. The more the injection pressure is the finer the mist will be. A finer mist will cool the intake charge more in less time. Nowadays injection pressures above 150psi till 250psi are common. 4. Injection Activation : Some are saying to inject at high levels of boost due to : - Compressor wheel damage at low boost levels (under 9psi) - Spooling is retarded due to colder EGTs If nozzle is small (measured in microns) and pressure is high (150+psi), wheel damage should never occur. Spooling should come earlier with pre-water injection due to thermodynamics pushing from adiabatic to isothermal having More Air per Less Turbo RPM equals to a better efficient compression. 5. PRE-Turbo vs Ambient Temps: This was rarely mentioned but surely is something to understand that at lower ambient temperatures, Mist is more difficult to mix with Air in time. 6. Check Valve Importance Through out the entire thread, this was an important factor to eliminate pooling. A check valve in the most vicinity of the nozzle with a high pressure rating works the best! 7. Injecting Hot/Boiling water Hot water is easier to make it Mist while Boiling Water makes a lot of pressure on it's own. What if we can use the "FREE" heat energy from the exhaust manifold itself. This could be done by fixing a copper tube right on the exhaust runners and press the hot water into the check valve than to the nozzle. |

|

#493

|

|||

|

|||

|

It is way beyond the technical/mechanical ability of an average user to create an near ideal system to meet the above criteria.

__________________

Richard L aquamist technical support |

|

#494

|

|||

|

|||

|

I've read all 50 pages, legitimately, condensing the main points to determine my own post-MAF setup and testing.

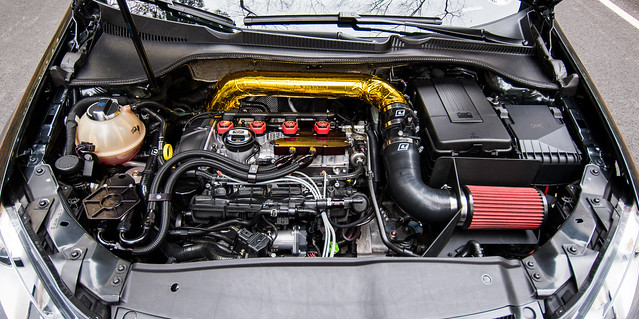

I've read here that for pre-turbo jets which can only be installed further upstream (post-MAF) and not at the compressor based on OEM turbo housings should be installed to spray against the direction of oncoming air post MAF to atomize most effectively (basically spraying at the back of the MAF housings the incoming air breaks up the fluid better). Based on my VW GTI's engine layout and more specifically the intake layout, I've been studying the air velocity within a 90 degree bend (the bend leading to the horizontal intake pipe running across the back of the engine (from the black MAF housing to the beginning of the long straight). VW GTI Intake layout:  This video shows in yellow the highest velocity stream which would help atomize any water meth spraying inside of this intake pipe: https://www.youtube.com/watch?v=OvprEu-yH-A Based on the video example alone, should I install the jet at the top of the horizontal pipe to spray against (into) the yellow stream? Or at the bottom of the pipe to spray into (with) the yellow stream? When people place jets within the intake tract, are they accounting for flow diagrams or streams? |

|

#495

|

|||

|

|||

|

Quote:

|

|

#496

|

|||

|

|||

|

Quote:

In the photo above the air flow runs towards the back of the engine/firewall then bends 90 degree left. I would like to install a small .3mm jet on the inside of the bend, right after the bend at the beginning of the long straight away running to the 2nd shorter 90 degree that runs down to the turbo inlet on passenger side of the car. This location should allow me to spray into the air velocity exiting the 90 degree bend and flowing through the straight away for atomization. |

|

#497

|

|||

|

|||

|

Quote:

I did this bracket (see attachment), thanking Richard for his suggestion, as I think it is the best option for water/air mix. Although some airflow will eventually be lost due to the bracket. The Pre-turbo setup is still not tried yet due to other work but will eventually within the next few months. Nozzle size is 150cc + another 150cc post turbo |

|

#498

|

|||

|

|||

|

I'm stuck since the compressor is buried down within the compressor housing of the turbo inlet. It's either test the smallest jet in some location or I can't test pre-turbo at all.

|

|

#499

|

|||

|

|||

|

Quote:

You can connect the bracket by using flexible hose pipes from one end to the other |

|

#500

|

|||

|

|||

|

Quote:

|

|

|

|