I've had an air atomizing pre turbo kit (500cc at 20 psi fluid pressure)

for some time that I've been running mechanically along with a Aquamist HSF 2 system

The nozzle fired into a gtx3071 with a 63 hotside on a Subaru EJ257, which if you're familiar with Subarus, is a rather restrictive setup on the exhaust side at high rpm and boost pressures. My thinking was to create a very broad torque by using wet injection to increase compressor efficiency and thereby reducing the exhaust energy required for a given flow rate. I was hoping that this would help to reduce EGBP a tad and give me a great responding street setup that was fun to drive but without the high egts typically associated with running small turbines (I know from experience that these combos are sensitive to timing increases)

While the setup appeared to run fine, it didn't seem logical to have invested in a PWM system only to have half of the system running 2 dimensionally. I've been bothering Richard and Jeff at Howerton for ideas to plumb the air atomizing nozzle into the Aquamist system. While it's easy to use restrictors to control flow and linearity, it seemed as though lowering fluid pressure to the atomization air pressure was the issue.

I did the following tests:

1) plumbed into the HSF2, with the flow valve on the air atomizing nozzle bottomed, I was able to get 300cc/min of flow with 100% duty cycle (HSF2 in test mode)

2) with air pressure on the line at 25psi, atomization quality appeared to be about the same as a standard aquamist injector (making the nozzle worthless)

I also noticed that, despite what others have argued as a non-isssue, I felt that this particular air atomizing nozzle's air ports were rather large, and when boost leak testing my intercooler pipes, it was clear that this bleeding would in effect require higher than average shaft speeds to at least reach the turn on point of the injection system.

After some thinking, I've come up with the following solutions.

1) After disassembling the Air Atomiznig Nozzle (AAN), I noticed that the system didn't use internal mixing. The chambers for fluid and air were separate. The atomization occured at the tip of the nozzle.

2) The separation block used 1/8 NPT ports.

3) Although the block had separate passages for fluid and air, there was a small hollow cavity on the fluid side.

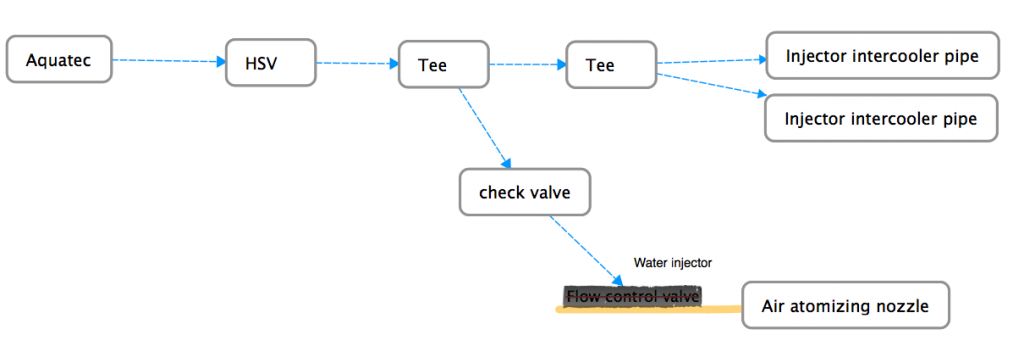

I found an old 1/8 NPT water injection nozzle rated at 300cc 200psi line pressure. I figured what the hell and screwed it in with a leftover check valve i had from a previous kit. Plumbed into the (diagram below) HSF2, I found that:

1) water flow was roughly 200cc per minute (aquamist pump is rated at 160psi)

2) pressure at the outlet of the AAN was significantly reduced

3) atomization quality increased significantly!!! I could get the droplet size to be much finer than the standard aquamist nozzle at max duty cycle even with lower air pressures (down to 10 psi)

Next, since I am running a standalone ECU. I decided to plug in MAC solenoid to interupt the air pressure (I have a 3d map for this) mirroring the activation of the HSF2.

Working together, immediately I noticed that

1) response has picked up significantly (the pressure bleeding although not significant enough to prevent pressurization is significant enough to delay spool by a tad)

2) The loss in torque right at peak boost pressure has disappeared but the top end has not. I could never get the 2 system to work together, even though I had the HSF2 on a separate table. I'm a bit obsessive compulsive about low load areas, and the slight dead spot at peak torque was driving me nuts. I didn't whether to pull fuel, pull PWM from the aquamist, or reduce the flow control valve on the AAN.

Yes I know that the purpose of the pumpless system is reliability and KISS. I'm not intending to argue otherwise. My reasoning was simply that I had a full PWM system, and I wasn't using it. Placing the water injector into the fluid port on the AAN and allows the pressure to dissipate as the fluid fires into the small cavity of the AAN. Fluid flow remains unchanged from the rating of the water injection nozzle. I am now on to serious testing, as I can stay in the car, examine logs and make adjustments without getting out. I just thought I'd share in case anyone wanted to combine theirs into one system. Although I've solved my the issues that I created for myself, I have more variables to play with. The beauty is that now I can add a failsafe to the system, as I can pull fluid flow from one line. I have PWM control over RPM and load (3d table). I don't have the data right now to export, but it's clear that, since I've likely reduced total flow by 20 percent, I have engine noise near peak torque (very bad). That was on my initial pull. I've increased the flow in those cells, and it went away. Now I need to think about the ratio of pre to post turbo flow, but I think I'll see how much torque I can wring out of this setup right now.

(water injection nozzle is on right side)

Here it is with the filter attached directly to the turbo. I plan to fabricate a cold air system soon.